Custom Fabrication

We pride ourselves in offering custom fabrication for parts and components to a wide variety of industries and applications. Machine builders, manufacturers and tool and die builders rely on us for accurately produced components – consistently delivered on time.

Our fabricated products department will meet your needs from start to finish of a project.

Whether you’re just getting started with a machine base or frame or nearing the end with worrisome sensor brackets and guarding Pro Metal Craft’s fabrications will exceed your expectations for fit, finish and timely delivery.

With more than thirty years of design experience, the skilled craftsmen of Pro Metal Craft have encountered countless variations of chutes, plenums, trays and covers so your application will be managed with experience and confidence.

That experience coupled with the very latest in technological advancements – such as fiber LASER cutting and polyester powder coat finishing – makes us uniquely capable to provide you with the level of accuracy in our parts that you have achieved throughout your build. We can accept information in many of the most current CAD formats such as Autodesk Inventor, Dassault Systèmes SOLIDWORKS or Autodesk’s Fusion 360 we are fully prepared to work with your information in its native format.

All of this equates to a no-compromise solution for your project needs.

Here are a few examples of what we can do for you:

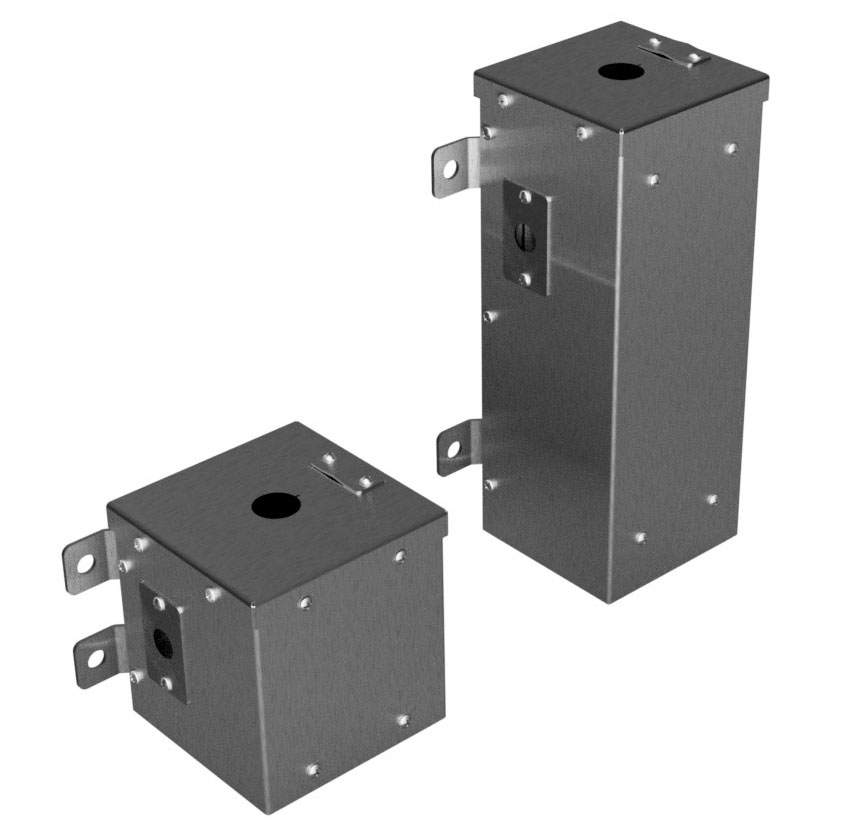

We have built HOUSINGS in all shapes and sizes to satisfy the imagination of our customers. The housings shown house high-temperature ceramic fiber heaters with operating temperatures up to 2200°F (1204°C) and are used in research facilities.

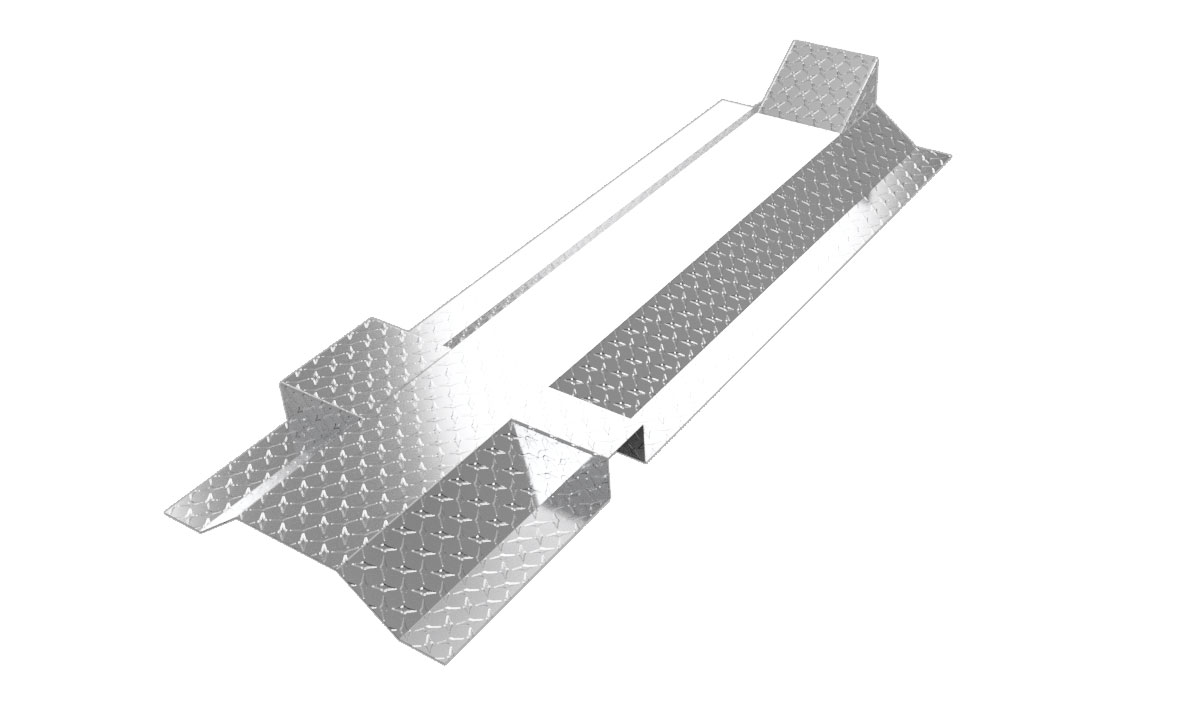

With a focus on public and worker health and safety many of our COVERS protect personnel from dangerous equipment. From belt covers to full machine surrounds, we have supplied an exhaustive gamut of covers to OEMs, installers, contractors and end users. The simple pipe joint cover shown – built in bright aluminum treadplate – was installed to prevent a trip hazard for a new machine installation.

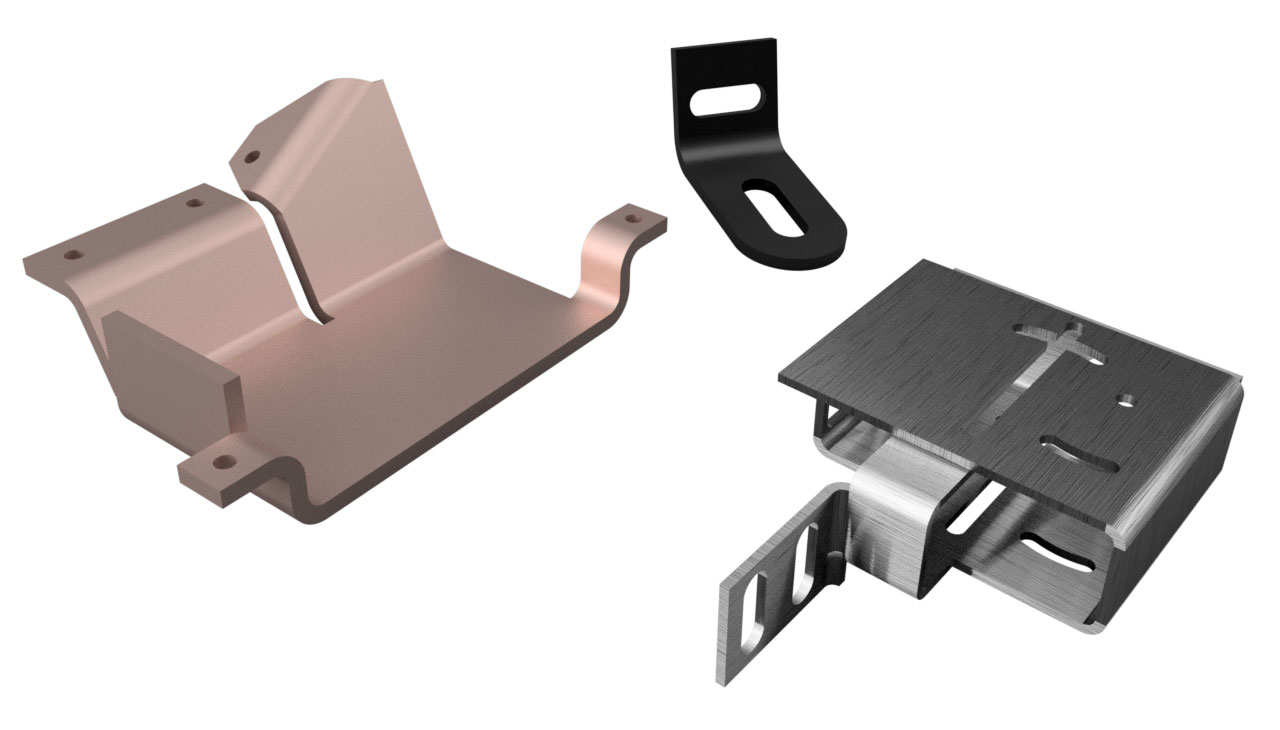

With our precision blanking, forming and welding capabilities we have produced a myriad of custom BRACKETS. Whether you’re mounting a sensor on a machine or new gauges in your beloved boat, we can help with quality grade materials, competent staff and durable finishes. We gladly consider projects of any size: from a single bracket to production runs.

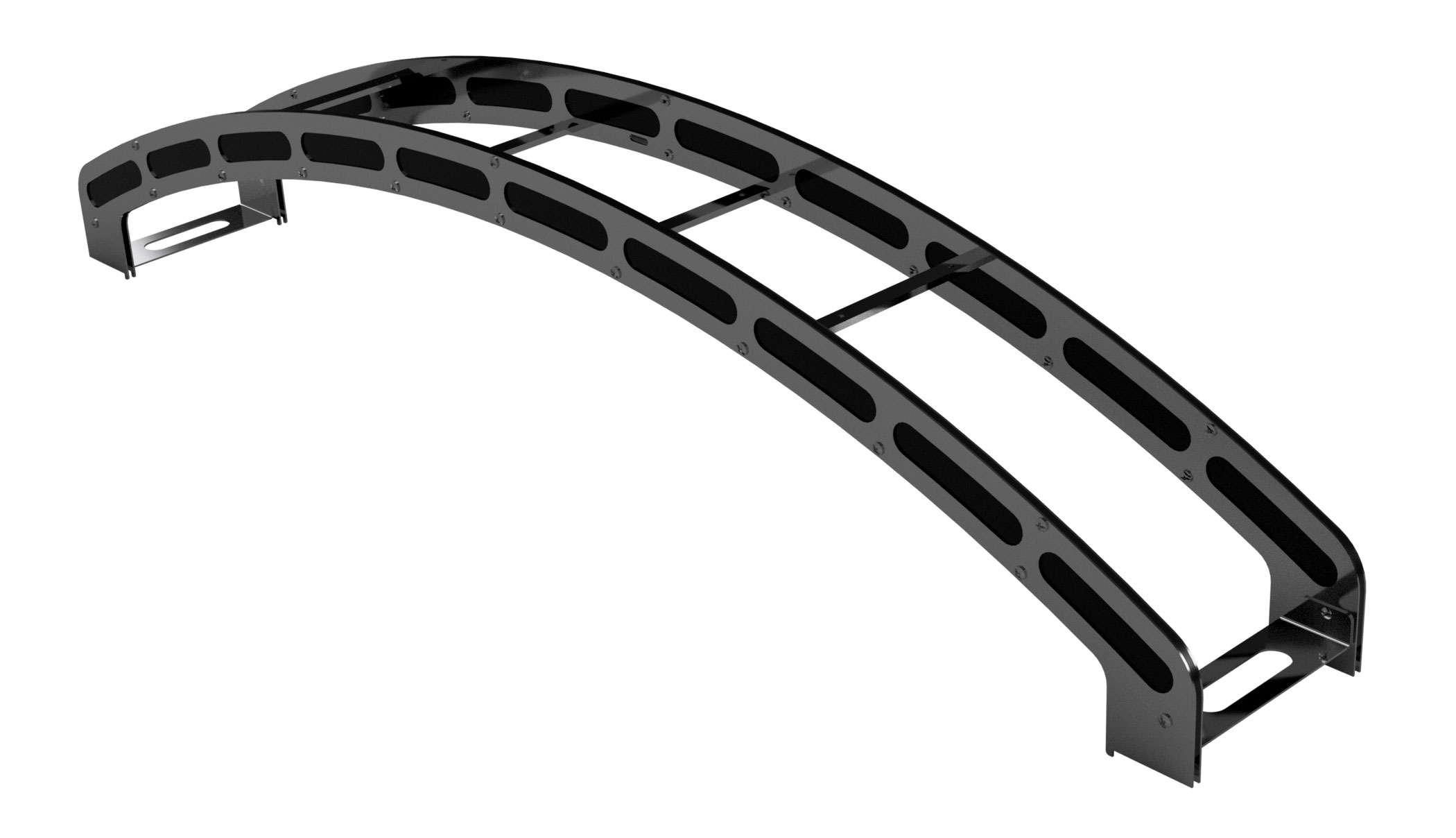

For equipment or control enclosure mounting our custom fabricated STANDS offer support, functionality and durability while retaining a cost-competitive edge.

Handling and diverting materials is a primary purpose of our CHUTES. Commonly incorporated at the machine design stage our precision custom made chutes ensure the intended travel of your finished goods and process scrap.

It’s hard to imagine a world without drive-thru windows now. Whether you’re accessing a parking garage, stopping for a coffee or a quick lunch you will find our STANCHIONS upholding card readers, intercoms, speakers and displays in all weather conditions.

Designed to enclose and isolate a hydraulic system from a top-mounted reservoir, this BASE was tested with computer simulated FEA to support the several thousand-pound operational load it would carry. Once skirted with gloss black acrylic sheeting this assembly provided a commercially appealing structure.

This suspension BRACKET – constructed in polished stainless steel with gloss black acrylic inlay – was custom designed to permit two LED light banks to straddle overtop a liquid display tank and even included wire channels for concealing the lamp cords.

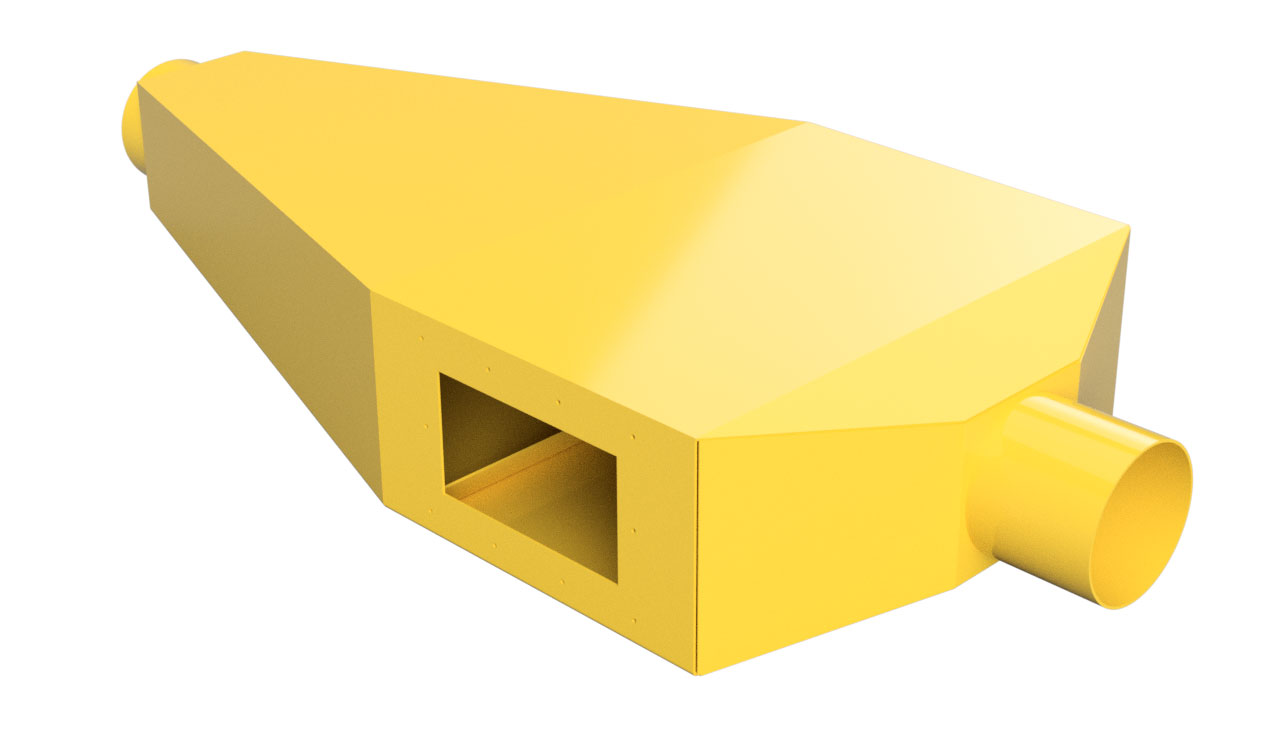

A common element in air distribution systems, we can offer custom PLENUMS to suit your needs. We satisfy customers in the automotive, HVAC, food and pharmaceutical industries with a variety of designs.

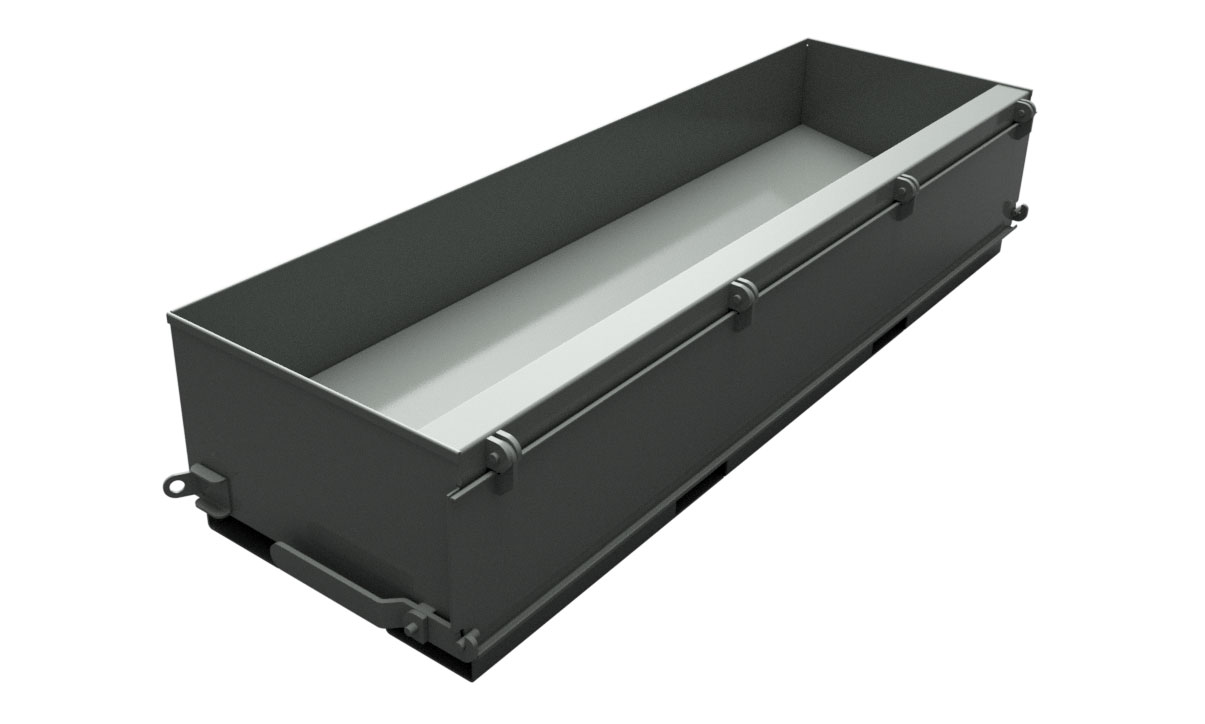

We have designed and built TROUGHS and TRAYS to contain numerous materials: from solids to liquids. The dump trough shown was custom sized to accommodate the scrap discharge from a machining operation in a production environment.