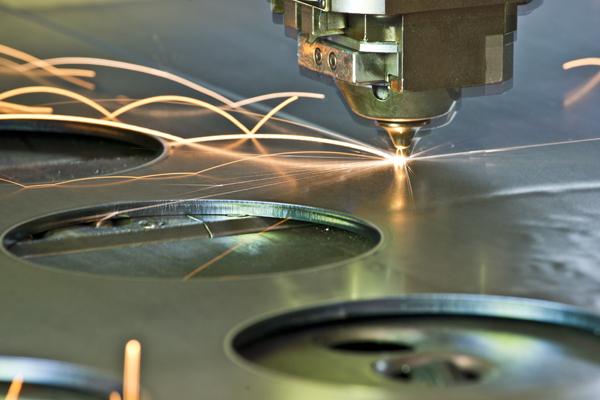

LASER CUTTING

Laser cutting is one of our metal profiling processes that directs a high-power laser through optics to cut materials for industrial and commercial applications. Laser cutting is more precise than plasma cutting although it is more limited in the thickness of material being cut. Pro Metal Craft offers both Fiber and CO2 lasers that can cut a number of materials including mild steel, stainless steel, aluminum, copper, brass, and exotic alloys. CO2 (carbon dioxide) laser excels at cutting, engraving, and boring metals, while Fiber laser is a good option for thicker materials.

Our custom laser cutting services offer a cost-effective and on-demand solution for your manufacturing needs. Sheet metal fabrication services range from low-volume prototype to high-volume production runs.

Advantages of Laser Cutting

Durability

Similar to CNC machining, sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

Scalability

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 10,000 production parts.

Material Selection

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

Custom Finishes

Select from a variety of finishes, including anodizing, plating, powder coating, and painting.

Rapid Turnaround

Combining the latest cutting, bending and punching with automated technologies, Pro Metal Craft provides instant sheet quotes and completed parts in as little 12 business days.

Laser Cutting Materials

Available Aluminum:

Aluminum 5052

Available Copper Varieties:

Copper 101

Copper 260 (Brass)

Available Steel Varieties:

Stainless Steel 301

Stainless Steel 304

Stainless Steel 316/316L

Steel 1018

Laser Cutting Finishes

Standard

Minimal post-processing or treatment on parts is done.

Bead Blast

The part surface is left with a smooth, matte appearance.

Anodize (Type II Or Type III)

Type II creates a corrosion-resistant finish. Parts can be anodized in different colors—clear, black, red, and gold are most common—and is usually associated with aluminum. Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Powder Coat

This is a process where powdered paint is sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer that is more durable than standard painting methods. A wide variety of colors are available to create the desired aesthetic.

Chem Film (Chromate Conversion Coating)

Provides corrosion resistance and good conductivity properties. Can be used as a base for paint. Can leave surface yellow/gold.

Advantages Of Laser Technology

Laser technology has the following advantages:

- High accuracy

- Excellent cut quality

- High processing speed

- Small kerf

- Very small heat-affected zone compared to other thermal cutting processes

- Very low application of heat, therefore minimum shrinkage of the cut material

- It is possible to cut complex geometrical shapes, small holes, and beveled parts

- Cutting and marking with the same tool

- Cuts many types of materials

- No contact between the material and machining tool (focusing head) and therefore no force is applied to the work-piece

- Easy and fast control of the laser power over a wide range (1-100%) enables a power reduction on tight or narrow curves

- The oxide layer is very thin and easily removed with laser torch cutting

- High-pressure laser cutting with nitrogen enables oxide-free cutting